Home made modular synth cases

As I’ve built and acquired more Eurorack modules I’ve been slowly working towards a setup which doesn’t require much additional outboard gear. I’ve upgraded a bit at a time and ended up with four small cases. A couple of problems have arisen from this. First, that some of the modules are too deep to fit in certain spaces, so I’ve had to locate them in places which aren’t intuitive to use or particularly convenient. And second, that using separate cases means I can’t really pre-patch anything before a gig, so setting up is long, complicated and stressful.

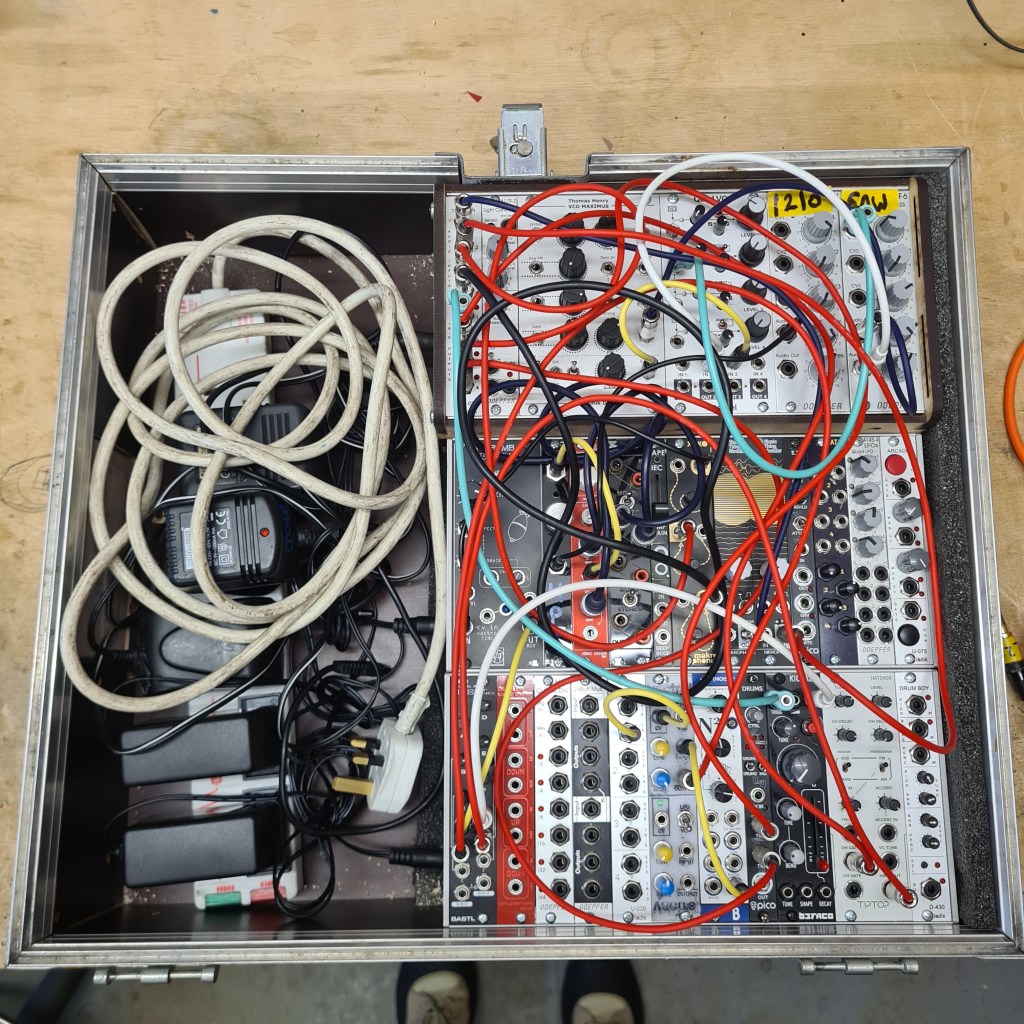

The last show I played was with DJ Food at Levitation Festival (short clip here) and I knew we would only have a short turnaround before going on stage. So I trialled putting three of the units into a flight case so I could pre-patch and save some time. It worked pretty well.

Taking this as a practice run I decided it would be worthwhile to turn this into a more long term solution and build a box to house the modules in. I’d already made a couple of small cases for the deeper modules in my collection, which used 4mm MDF and extruded aluminium rails. So I knew the basic principle would work, and just needed to make them. Here’s one of the smaller cases, which I’ve just recently spray painted. These are the modules I’ve designed recently which all use an Arduino so just take a 5V power input. That is, apart from the Motor module which has its own 12V supply. I added the air vents to the sides primarily for the Motor module, which has some pretty big heat-sinks on the drivers. The 4mm square holes leave enough material for the sides to be rigid too.

The initial plan for the new one was to make a case which would be the same dimensions as a Technics SL-1200 turntable, for the primary reason that I have a ‘deck saver’ plastic lid which I don’t use, which would make a good lid for the unit for transporting the pre-patched modules. Testing a couple of orientations, the most efficient way seemed to be orientating it portrait-wise which would give three 69hp rows of 3U rackspace and one row of 1U. Surprisingly and serendipitously, using 4mm material this fits EXACTLY to the millimetre. The clearance of the unit allows for my deepest modules (Doepfer A-103 filters at over 50mm) to comfortably fit with some room for cabling, meaning no more awkward decisions about which module to put in an inconvenient place. I’m pleased with the outcome apart from the fact I made it very slightly too wide to fit the deck saver lid – somewhere in the design I added 4mm to the width, annoyingly. Not enough of an issue to re-cut though.

The other main intention with this build was to try to save money buying something off-the-peg. I’m fairly sure I have done that – fully made cases this size are wildly expensive – but this wasn’t cheap to make by any means, as there are lots of components apart from the case:

- Rails are extruded aluminium as sold by Synth Racks in the UK [link]

The case holds 69hp per row, so 8 pairs are required. I bought some of their old stock cheaply on ebay, which needed cutting to size and re-joining per strip. You can use M5 threaded rod to join two pieces. The end bolts are M5 too. The aluminium is soft enough that you can bolt into the cut end without needing to thread it. - Power for the whole case is a 2MS Row Power 45 module. It seems great so far, and should have enough wattage to run the modules I have. It’s not cheap though – and you need to buy both the power supply and cable for it extra!

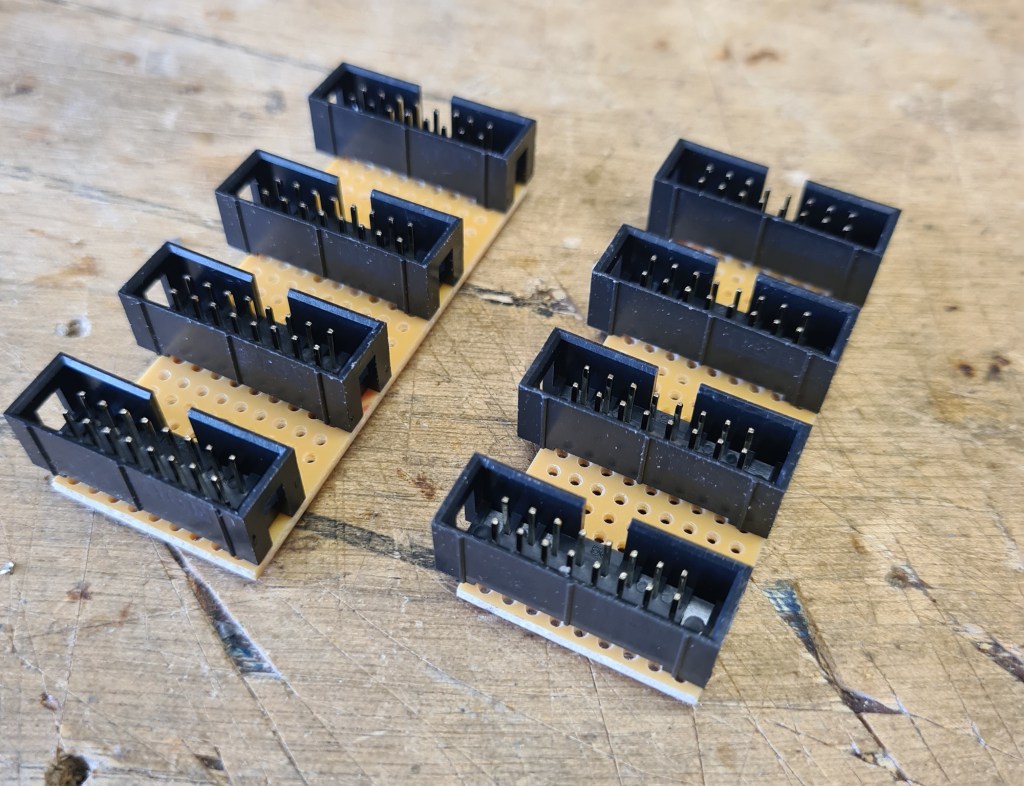

- For power distribution I bought some ‘flying bus cables’ from Thonk. [link] The Row Power has two sockets and I daisy-chained the third. I still didn’t have enough sockets so made some passive bus boards from vero-board and 16-pin sockets, like the ones below but longer. To be honest it doesn’t feel ideal daisy-chaining them like this, but according to the Row Power user manual this is a legitimate way to do it.

- Finally spray paint. I’m not a huge fan of bare MDF with laser scorch marks, though I do have a lot of stuff like that mainly due laziness in not painting it. I bought cheap furniture primer from the local pound shop and then used some good quality spraypaint to finish. The reason for the unusual colours is that someone in my studios was offloading a bunch of half-used cans.

A couple of folks have asked for the vector files for these cases, which is the main reason for this post. Here they are as vector files:

Small case vector file (svg)

Large case vector file (svg)

If you end up making one of them, please let me know how you get on!